- 0531-87887788

來源:http://m.gbpeixun.com/ 發布時間:2022-03-31

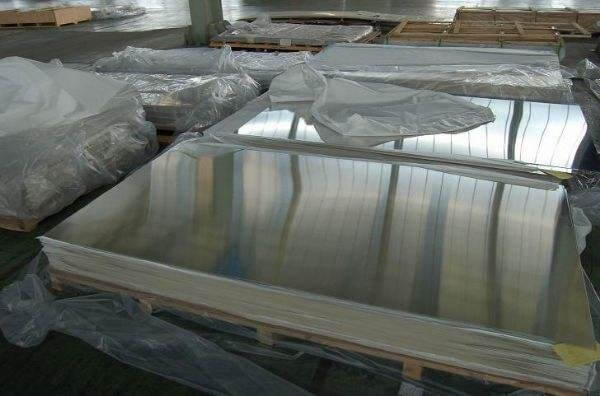

鋁板在應用全過程中,在所難免碰到很多問題,一些問題則是因為在中后期應用全過程實際操作不善造成的。因而,鋁板生產廠家下面來講講鋁板油脂處理事項。

Aluminum plate in the whole process of application, it is inevitable to encounter a lot of problems, some problems are caused by poor practical operation in the whole process of application in the middle and late period. Therefore, aluminum plate manufacturers will talk about the following aluminum plate grease treatment matters.

油漬并并不是指鋁板出產進行后沾帶的,只是在開展鋁板的冷軋后,鋁板生產廠家在鋁梢外表帶了過多的油,而且還附加了除軋制油膜之外的剩下油脂,在中后期對產品開展查詢和分割出產時,便會在外表發覺這種人眼由此可見的油脂。

Oil stains and does not mean that after stained with aluminum plate production, just after cold rolling of aluminum plate, aluminum plate aluminum manufacturers in tip appearance brought too much oil, but also added the remaining oil, except rolling oil film in the middle to produce products to carry out the query and segmentation, will be found out that the human eye so grease in appearance.

鋁板去除油脂后,必須去除氧化物。為了除去氧化物,有必要從鋁板的表面物理性地剝離材料。必須確認刷子干凈,好使用有柔軟毛的刷子比重的刷子。這是因為,不是去除,而是有擦拭氧化物的可能性。另一個選擇是化學清除。

After grease removal, the oxide must be removed from the aluminum plate. In order to remove oxides, it is necessary to physically strip the material from the surface of the aluminum plate. Make sure the brush is clean, preferably one with soft bristles. This is because, instead of removing, there is the possibility of wiping the oxide. Another option is chemical removal.

該方法的理想選擇是強堿溶液。可以將工件完全浸入解決溶液中,也可以使用噴霧瓶除去氧化物。這些溶液通常以磷酸為基礎,或者可能含有氫氟酸,所以使用這些溶液時請充分注意。無論使用哪個選項,在清洗金屬之后,必須等待足夠的時間才能完全干燥。

The ideal choice for this method is a strong base solution. The workpiece can be fully immersed in the solution or the oxide can be removed using a spray bottle. These solutions are usually phosphoric acid based or may contain hydrofluoric acid, so be careful when using these solutions. No matter which option you use, after cleaning the metal, you must wait enough time to dry it completely.

,必須確認焊接的金屬中沒有油脂。這因為鋁板中的雜質影響焊接,可能導致缺陷。金屬表面用肉眼看起來很漂亮,但是很容易擦掉不能去除的油、油脂和其他液體。很多人用布或刷子擦金屬,但不能有效地去除油脂。只是在周圍走,情況就會惡化。

First, make sure there is no grease in the welded metal. This is because impurities in the aluminum plate interfere with welding and can lead to defects. Metal surfaces look nice to the naked eye, but are easy to rub off oils, grease, and other liquids that cannot be removed. Many people rub metal with a cloth or brush, but this does not remove grease effectively. Just walking around, things get worse.

難道說沒有辦法在出產時就避免這種問題嗎?自然并不是,實際上鋁板生產廠家可以在出產鋁板前就對出產機器設備開展綜合嚴格查詢。假如在機械設備中本身就會有很多油脂,就應當立即清理并尋找緣故妥善處理。更多內容來http://m.gbpeixun.com咨詢。

Is there no way to avoid this problem at the point of production? Nature is not, in fact, aluminum plate manufacturers can produce aluminum plate before the production of machinery and equipment to carry out a comprehensive strict inquiry. If there will be a lot of grease in the mechanical equipment itself, it should be cleaned up immediately and find a reason for proper handling. More content to http://m.gbpeixun.com.