- 0531-87887788

來源:http://m.gbpeixun.com/ 發布時間:2021-02-13

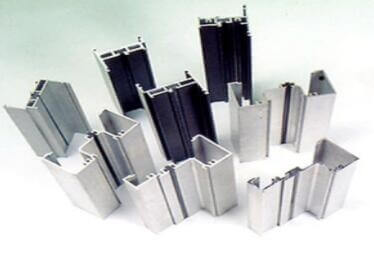

鋁合金的陽極氧化越來越多,可以應用于日常生活中。由于該工藝的特點,鋁件表面有一層堅硬的保護層,可用于生產廚房用具等日用品。但鑄鋁的陽極氧化效果不佳,表面不光亮,只能是黑色。鋁合金型材稍微好一點,下面簡單介紹一下鋁板氧化處理的方法。

More and more anodic oxidation of aluminium alloys can be used in daily life. Due to the characteristics of this process, the surface of aluminium parts has a hard protective layer, which can be used to produce kitchen appliances and other daily necessities. However, the anodic oxidation effect of cast aluminium is not good, the surface is not bright and can only be black. Aluminum alloy profiles are slightly better. Here's a brief introduction to the oxidation treatment of aluminium plate.

鋁板生產廠家

Aluminum plate manufacturer

近十年來,鋁氧化著色技術在我國得到了迅速發展。許多工廠采用了新技術,在實際生產中積累了豐富的經驗。鋁及其合金的陽極氧化工藝有許多成熟的、正在發展的方法。

In recent ten years, aluminium oxide coloring technology has developed rapidly in China. Many factories have adopted new technologies and accumulated rich experience in actual production. There are many mature and developing methods for anodizing aluminium and its alloys.

鋁板生產廠家

Aluminum plate manufacturer

在選擇氧化工藝前,先了解鋁或鋁合金材料。因為,材料的質量、組成的不同,將直接影響到鋁產品陽極氧化后的質量。洪菊德、范吉對此有專門的評論(見電鍍與精加工,no。2、1982年,P.27)。

Before choosing the oxidation process, we should know about the aluminium or aluminium alloy materials. Because the quality and composition of materials will directly affect the quality of aluminium products after anodizing. Hong Jude and Fanji have special comments on this (see Electroplating and Finishing, No). 2. 1982, P.27).

鋁板生產廠家

Aluminum plate manufacturer

例如,鋁表面的缺陷如氣泡、劃痕、剝落、粗糙等,經過陽極氧化后仍然會出現所有的缺陷。合金成分對陽極氧化后的表面形貌有直接影響。

For example, defects on the surface of aluminium, such as bubbles, scratches, spalling, roughness, etc., will still appear after anodizing. The composition of the alloy has a direct influence on the surface morphology after anodizing.

例如,含1-2%錳的鋁合金氧化后呈現棕藍色。隨著鋁中錳含量的增加,氧化后的表面顏色由棕藍變為深褐色。

For example, aluminium alloys containing 1-2% manganese show brown-blue color after oxidation. With the increase of manganese content in aluminium, the surface color changed from brown blue to dark brown after oxidation.

含硅0.6 ~ 1.5%的鋁合金氧化后呈灰色,含硅3 ~ 6%的鋁合金呈白色。

Aluminum alloys containing 0.6-1.5% silicon are grey after oxidation, and aluminum alloys containing 3-6% silicon are white.

鋅的呈乳白色,鉻的呈金色到灰色,鎳的呈淡黃色。

Zinc is milky white, chromium is golden to gray, and nickel is pale yellow.

一般來說,只有鋁含鎂和鈦超過5%才含有金,可以氧化得到無色、透明、明亮、干凈的外觀。

Generally speaking, only aluminium containing more than 5% magnesium and titanium contains gold, which can be oxidized to a colorless, transparent, bright and clean appearance.

在鋁及鋁合金材料的選擇中,有必要考慮選擇合適的陽極氧化工藝。目前,我國廣泛采用的硫酸氧化法、草酸氧化法和鉻酸氧化法已在手冊、書籍和期刊上詳細介紹。

In the selection of aluminium and aluminium alloy materials, it is necessary to consider the appropriate anodizing process. At present, sulfuric acid oxidation method, oxalic acid oxidation method and chromic acid oxidation method widely used in China have been introduced in manuals, books and periodicals in detail.

以上是鋁板生產廠家為大家整理的相關內容,想要了解更多內容,歡迎訪問網站:http://m.gbpeixun.com

Above is the related content that the aluminium plate manufacturer arranges for everybody, want to know more content, welcome to visit the website: http://m.gbpeixun.com